Quality

We only use the best equipment IMPORTED from all around the world. As our playground and park equipment are used by the young and old , we place a premium on quality and safety on our products & systems.Play system is developed by a a specialised team with extensive and unparralled skills in Designing and constant R&D to ensure all International Standards are met in terms of design, aesthetics, product life and most importantly CHILD SAFETY.

Why Choose Playco Products?

LLDPE Rotational Molding

Linear low density polyethylene, or LLDPE, is petroleum based plastic commonly used in rotational molding. A competitive approach to plastic manufacturing, the process consists of introducing a plastic resin in powder form into a hollow, shell-like mold. The molds are held by a machine arm that is engaged and sent into biaxial rotation, at relatively low speeds. As the plastic is heated, it forms a thin layer against the mold surface. After the cooling phase of rotation, the product can be removed from the mold. LLDPE rotational molding is used in a variety of applications including: industrial hoppers, toys, playground equipment,containers and outdoor recreational products.

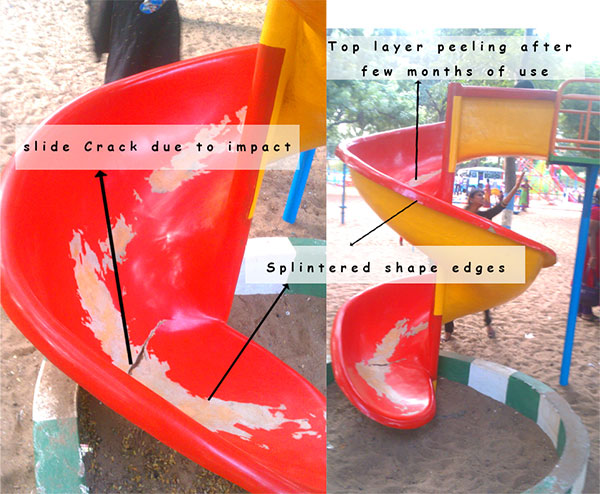

FRP-Fiber reinforced polymers

Problem keeping the allowable flex in the structure below the flexible capabilities of the FRP. This will result in your FRP developing cracks and ultimately failing. Also have to be concerned with UV embrittlement, impact resistance (like in a crash).

Please note: We never use FRP material in our play equipment’s. Condition of FRP Material playground Less than Two year.

We only use imported virgin LLDPE ( LINEAR LOW DENSITY POLYETHYLENE) material & HDPE ( HIGH DENSITY POLYETHYLENE) which will not get corroded, rust proof, bright colors, No peeling / hard edges, material wall thickness will be 8mm. Self-life around 10 years.

Material Description

We use eco-friendly, anti-static, anti-ultravoilet and non-toxic matereials.They are easy to assemble with innovative designs & bright colors. The plastic parts put on an excellent performance in weather fastness, toughness, intensity, ageing resistance. In bright color and beautiful appearance, they are colorfast and durable in use.

Polyethylene

Polyethylene parts of our products are manufactured by rotational molding of LLDPE imported from Samsung Corporation in South Korea. And the wall thicknesses of the plastic parts are above 8mm.

Main Column

All the main columns are made of galvanized steel pipes with diameter of 114mm and wall thickness of 2.2mm. Quality and technical standard meets the requirements of EU standards.

Platforms

All the platforms are shaped by piercing 2.2mm-thick cold-roll steel sheet, with bores of diameter 6mm. The quality and technical standard are conforming to the European EN1176 standard.

Other Metal Parts

All the metal parts are made of galvanized steel pipes with diameter of 60mm, 48mm, 38mm, 32mm, 28mm and wall thickness of 2.2mm. Quality and technical standard meets the requirements of EU standards. Breitling Navitimer Replica

Fittings

All the metal fittings are made of high strength aluminum alloy of one-time cast forming. After polishing processing, all the sharp corners are round and smooth. All the screws are made of stainless steel #314, which meets the EU standards.

Ropes and Nets

The ropes and nets are imported high quality sailing ropes with diameter of 14mm &16mm, containing an internal of high strength galvanized steel wire.

Our Manufacturing Facility

Ware House

Playco playgrounds are designed to meet the highest standards of safety, durability, and performance — creating joyful play experiences that last for years.

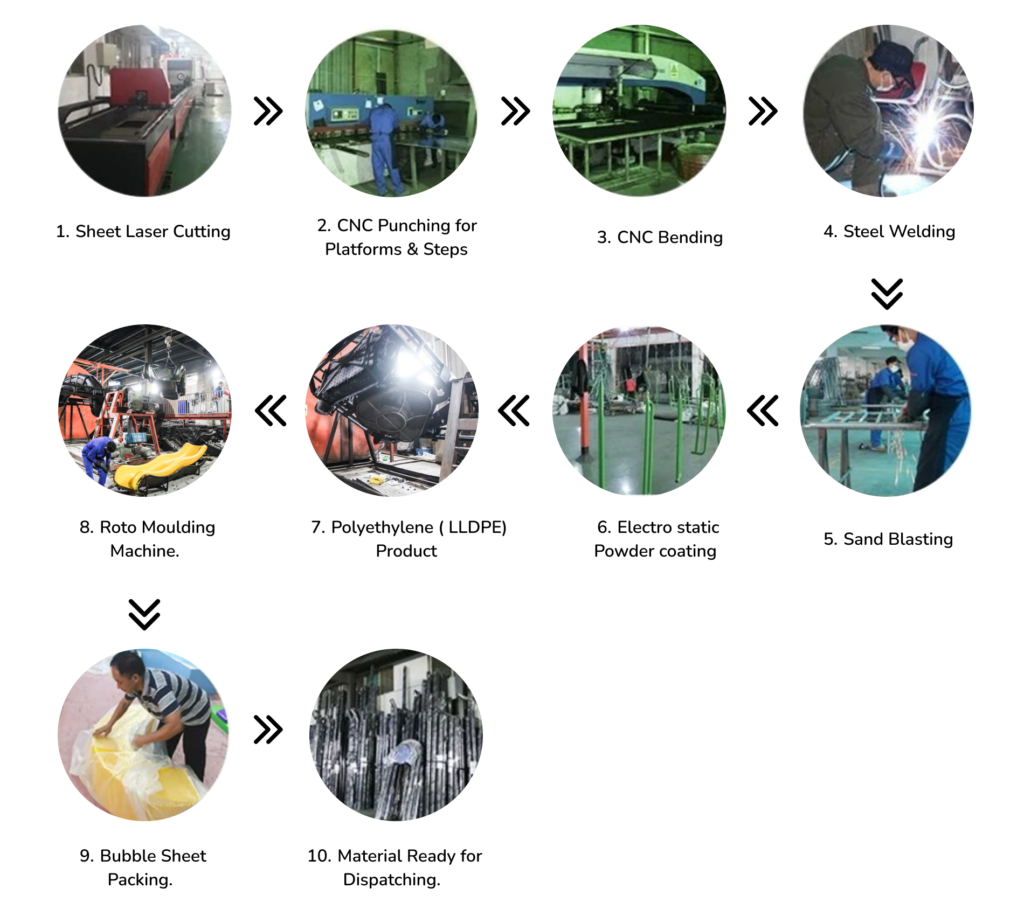

How do we make products?